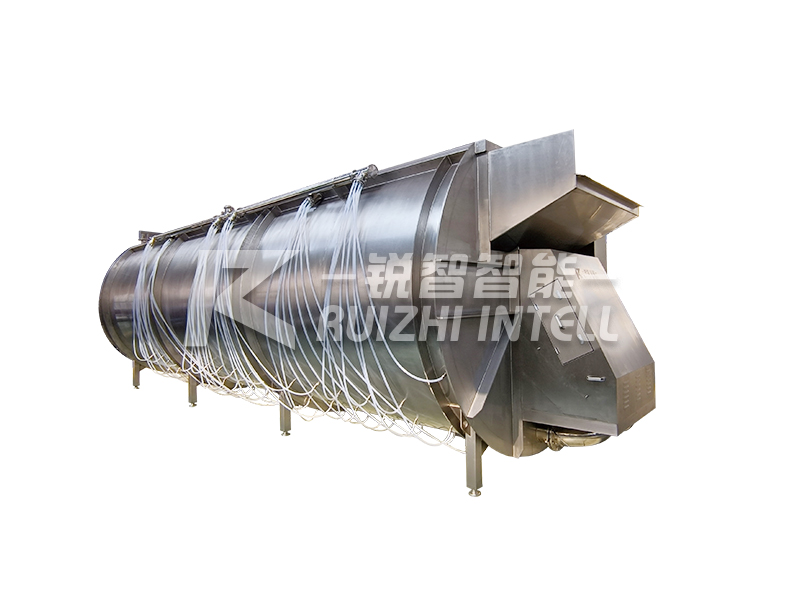

The rotary chilling is one of the main equipments in the poultry slaughtering production line. It is used to cool, clean and sterilize the poultry carcass after the poultry is eviscerated.

The tree-shaped explosion pipeline arrangement is adopted to ensure the balance of wind pressure and air volume at all points inside machine.

The balanced design of each explosion point on the tank body ensures that the passing poultry carcasses are fully stirred and the poultry carcasses are not refluxed.

According to these two designs, the machine can ensures that the passing poultry carcass can obtain the best cooling effect and water absorption rate under the condition of the same poultry-water ratio per unit time.

The sealing structure of special material is used between the main shaft of the driving end and the end plate, and the service life of the seal can be as long as more than 10 years, which avoids the problem of water leakage caused by the aging of the rubber seal ring and needs to be replaced.

The design of the helical poultry body propeller ensures that when the water flow is different, the helical blades will not block the aeration and float below it during the process of pushing the poultry body forward.

The food-grade pneumatic hose is used instead of the plastic clamping tube, which is beautiful and hygienic, with a greatly improved service life and easy replacement.

简体中文

简体中文 English

English